Description

WE ARE YOUR

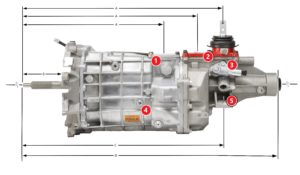

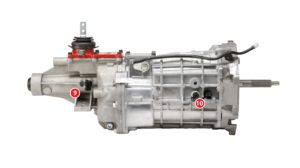

Introduced in the spring of 2009, the TREMEC T56 Magnum 6-speed manual transmission, was the long-awaited and highly anticipated replacement for the original T56.

Based heavily on the TR-6060, the all-new Magnum took the best of TREMEC’s current OEM design and manufacturing technologies and combined them with the most popular features of their intensely popular TKO 5-speed.

The result is the smoothest shifting, greatest driving, strongest, and most versatile 6-speed aftermarket transmission TREMEC has ever produced.

Features & Benefits:

- 85mm center distance.

- 700 lb-ft effective torque capacity.

- A fully reversible die-cast aluminum shifter for smooth, positive shift action.

- Dual ‘speedo’ pick-ups to accommodate both electric and mechanical type speedometers.

- Built-in mid-shift provisions under inspection cover for simple, pain-free mid-shift conversions.

- Triple cone synchronizers on gears 1-4, double cone synchronizers on gears 5-6, as well as reverse.

- Accurate, smooth, high-rpm shift capabilities.

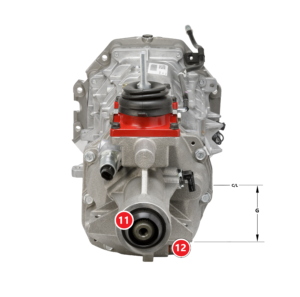

- 26 Spline input shaft

- 31 Spline output shaft

Experience the MDL difference:

When you purchase a complete MDL Conversion Package you get

-

- We extend the manufacturer’s warranty by an extra year… with a 1-year grace period.

- We have the best in the industry customer service.

- lifetime technical support.

Get your new T56 Magnum on the road with our Performance T56 Magnum Installation kit featuring bell-housing, flywheel, clutch, clutch release we have mechanical or hydraulic actuation, bearings, pressure plate, with all the supporting hardware, and more.

Please see our Solutions section for whatever you hit the road with.

INFO

Road and Track / Brian Silvestro / May 25, 2021 (Illustrations: Steven Wilson)

The manual transmission was eclipsed years ago, replaced by smarter, quicker, more efficient gearboxes that demand less from a driver. So why exactly do we cling to the stick so tightly? It?s just a collection of gears, forks, rods, and bearings, after all. Well, a well-made shift-it-yourself ?box can elevate even the best driving experience, adding layers of involvement and satisfaction.

The T-56 is one such transmission. BorgWarner designed the T-56 to tame the Dodge Viper?s torquey 8.0-liter V-10. The T-56 and its successor, the TREMEC TR-6060, have since made their way into droves of legendary performance cars.

To this day, it?s the go-to gearbox for tuners who need a well-made, fun-to-use transmission that can take a beating.

Perhaps that?s where the future of three-pedal cars lies, with enthusiasts who know just how critical changing gears is to the act of driving. So long as enthusiasts exist, there will be a market for gearboxes like the TREMEC T-56.

This story originally appeared in Volume 6 of Road & Track.

BREAK-IN/DRIVING

Driving Techniques

A 500-mile break-in period will prevent premature wear and possible damage to the transmission. During the

break-in period, you must avoid high RPM shifts and “drag” starts. The clutch must be fully disengaged to shift

the transmission. Do not use excessive force when shifting the transmission. If you experience clash shifts

(grinding), check clutch travel to ensure proper air gap is achieved. Another possible cause of clash shifting is

improper transmission installation (excessive driveline angle / resulting in poor driveline alignment). Do not hold

the transmission in gear by applying force on the shifter. This will damage the pads on the shift forks and may

result in significant damage to the transmission.

![]()