Here’s How… To Get A light Clutch Pedal with MDL’s LF-Series Hydraulic clutch System

Here’s How…

To Get A Light Clutch Pedal

With Modern Driveline’s LF Series Hydraulic Clutch System

Modern Driveline’s LF Series Hydraulic Clutch Kits for classic cars make light work of a heavy pedal by letting fluid do the hard work mechanical Z-bar clutch systems have been doing for generations. Modern Driveline has taken the hydraulic clutch concept and made it an even better system by making it easier to install and service. Simply put, our hydraulic clutch system for classic Z-bar and cable clutch applications is the best in the industry.

You won’t find a better engineered system out there because we install, use, and race what we sell on our own cars. What’s more, we’d like you to know the benefits of our hydraulic clutch systems by installing one of them on your vehicle.

Modern Driveline’s LF Series Hydraulic Clutch Systems are a revolutionary way to put a hydraulic clutch in your classic muscle car or late-model performance ride. Our LF systems aren’t just another generic “one size fits all…” hydraulic clutch conversion kit but instead a fresh approach to pedal and master cylinder geometry that reduces pedal effort significantly. What’s more, they’re the easiest to install and adjust. The hydraulic clutch master cylinder is resized and optimized for your specific application.

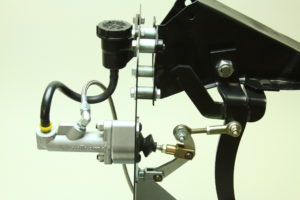

The LF Series hydraulic clutch system employs a revolutionary design that improves clutch pedal geometry as it relates to the clutch master cylinder along with a revised bore size. The master cylinder itself is resized and optimized for clutch modulation. The small master cylinder size insures it will fit in the majority of applications. Our linkage makes it possible to use the mechanical clutch linkage rod hole (where possible) allowing positioning perpendicular to firewall, and provide mechanical advantage thus reducing the pedal pressure required to operate the clutch. The mechanical linkage design also allows the full stroke of the pedal to maximize clutch modulation.

Modern Driveline’s external clutch slave cylinder is an intended replacement for the cable clutch system using the same fork and throwout bearing. It mimics cable operation without the complexities of a cable system. The light clutch pedal feel and improved throw is an improvement beyond all other hydraulic clutch kits on the market. A full 1 1/4″ throw insures complete clutch disengagement.

The Modern Driveline internal hydraulic release bearing is high-end Tilton quality with braided hoses and an integrated bleeder. This is the 6000 Series Tilton hydraulic releases throwout bearing that installs onto the transmission’s forward bearing retainer. Designed to work with most bellhousings and transmissions (T5, TKO, T56), the Tilton 6000 will even bolt onto your vintage Ford Top Loader four-speed.

Modern Driveline’s external clutch slave bolts onto the bellhousing by drilling a couple of 3/8-inch holes in your cable clutch style bellhousing, installing the slave cylinder mounting bracket and slave. Installation is simple and takes about one hour.

Slave cylinder actuation rod ties into the clutch fork as shown and is fully adjustable. Once clutch system bleeding is complete adjust the clutch fork.

Hydraulic clutch master cylinder firewall location gets a one-inch hole, which is bored with a hole saw as shown. Location will vary depending upon model year and vehicle type. Use the clutch master cylinder mount as a template.

The hydraulic clutch master cylinder under-dash mount and linkage are located here just below the firewall transition plug on classic Mustangs as one example of what we sell. As you can see here we haven’t bored the master cylinder hole yet. This really is a simple system to install and adjust. The greatest challenge is for you to get the dimensions right per your Modern Driveline instructions. If you encounter a snag we’re to help with great technical support throughout the week.

Modern Driveline master cylinder is mounted as shown here at the firewall. This is a 1965-66 Mustang, but expect most applications to be similar — especially Falcon, Comet, and Cougar. Reservoir, which is mounted on the firewall, still needs to be connected to the clutch master cylinder.

Slave cylinder is bled underneath as shown once the reservoir has been serviced with brake fluid. Take care never to spill brake fluid on paint. Permanent damage can result. Both ends of the bleed hose must be sealed tight to keep air from contaminating the fluid. Hose end should be submerged in brake fluid. Have a helper slowly depress the clutch pedal fully, then, close the bleeder. Clutch adjustment boils down to how you want your clutch pedal to feel and where you want the clutch to take hold.

Always look to your Modern Driveline tech support team. We’re here to help you with your hydraulic clutch installation should you have any problems. Because we have installed these systems ourselves on many occasions we understand your challenges better than anyone in the industry. When you call for tech help you’re not getting someone with a sales quota, you’re getting someone who understands your problem who can help and get you back on the road.

Please log in to leave a comment.

No Comments Yet