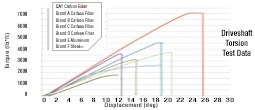

QA1 Carbon Fiber Driveshaft Technology

Raising the Bar with American-Made Driveshafts

QA1 is redefining industry standards by performing filament winding in-house, – a necessary process to design and produce the correct torsional stiffness specifications for world-class carbon fiber driveshafts. It is imperative to have control over the entire filament winding process, and by having the specialized equipment in-house, QA1 is able to customize tube length, wall thickness, and pattern, enabling products such as carbon fiber driveshafts to be designed and wound for specific applications. QA1 designs, engineers and manufactures unique composite components, enabling the customization of tube dimensions for customer requirements.

Cutting Edge Capabilities

Equipped with sophisticated 3D modeling programs and machines such as a torsional dyno, balancer, tensile tester, filament winder, robotic welder, coordinate measuring machines, CNC machines, and tube benders, QA1 is able to take projects from initial design concept to complete assembly, all under one roof.

Benefits of a QA1 Carbon Fiber Driveshaft

Learn More

Link for Carbon Fiber Build sheet with 1310 U-Joint

Link for Carbon Fiber Build sheet with 1350 U-Joint

If you’re looking for more information or a quote for your project send us your details and we’ll get back to you with a quote. Or call…

208-453-9800

Please log in to leave a comment.

No Comments Yet