How the TREMEC T56 MAGNUM 6-Speed transmission is improved.

The improvement is in the Beef

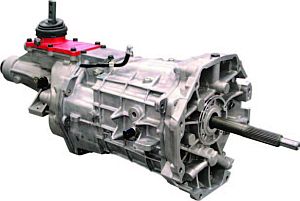

The kingpin of TREMEC’s high-performance line-up, the all-new T56 Magnum 6-speed transmission takes the very best from current OEM technologies and pairs it with the most popular features of the all-business TKO & TKX 5-speeds.

Able to withstand a massive 700 lb-ft. of torque, while providing unbelievably crisp shifts.

No other manual transmission on the planet offers as much combined strength, versatility, and general ease of use as the T56 Magnum.

Known in its O.E. form as the ‘TR6060’, the Magnum is an aftermarket version of the same transmission found in many of today’s most celebrated factory supercars–including the ZR1 Corvette and sinister ACR Viper. A world-class transmission in every respect, it’s the best transmission on the market for those who will accept nothing less.

Just what is it that makes the TREMEC T56 Magnum better than its predecessors? Beefiness. Gears, shafts, bearings, synchros, the case, and forks were all dimensionally increased for better torque handling capacity.

The Beef

With gear ratios being the only direct carryover from the original T56, the Magnum is truly a brand new transmission from the ground up.

Of the many substantial upgrades, those listed below will, in the long term, likely be the most pertinent and sought-after features that will set the T56 Magnum apart from the rest.

Gears

Helping greatly to achieve the Magnum’s remarkable 700 lb-ft. torque capacity rating is all new speed gears similar to those found in the TREMEC TR-6060. These gears feature substantially increased face widths, which are easily noted when compared to a like-speed gear from an original T-56 (as shown at the bottom left).

Also especially noteworthy is the fact that these new speed gears benefit from a significant advance in manufacturing techniques—two-piece laser beam welded construction.

Past units were one-piece forgings that suffered machining limitations. These new two-piece units allow for much greater control of tooth angles, pitch, alignment, and more, while also featuring built-in positive stops (shown at the top) to virtually eliminate the possibility of ‘over-thrown’ shifts.

Countershaft

Another critical aspect of the Magnum’s improved strength over the previous T56 is the radically bolstered one-piece countershaft (shown at right, positioned on left). Strength benefits are obvious and abundant. This larger shaft not only resists distortion far better than previous designs but also prompted the use of larger bearings in all critical support areas for extraordinary stability. The image at right also serves as another excellent representation of the increased face widths on the T56 Magnum gears.

Input Shaft

The Magnum’s input shaft (positioned on right) represents another significant strength upgrade for the transmission’s first line of defense. Improvements include additional material throughout the length of the shaft, increased face width, a larger input bearing, and generously long splines to accommodate twin-disc clutch setups. As an additional strength consideration, all Magnums will come equipped with 26-spline input shafts. 10-spline ‘Ford-style’ units will not be available.

Synchronizers

Allowing the space for the Magnum’s wider gears is one of the cornerstones of its development—cutting-edge compact synchronizer technology. These all-new synchronizers are considerably narrower (top image, left) than their T56 counterparts (top image, right) and feature fine pitch tooth angles to effectively decrease the amount of travel necessary for engagement. Not only are shift throws shortened, but thanks to new spring-loaded ball-type inserts (bottom image, left), friction is greatly reduced; resulting in lower shift efforts and reduced ‘double-bump’ during shifts—also known as better shift feel.

Shift Forks

Yet another substantial part of the Magnum’s unparalleled performance are the redesigned shift forks (shown at left, rear position) featuring integrated ‘shift keys’ to virtually eliminate the possibility of bending shift forks. In such cases related to the original T56, this action typically referred to as ‘bending’ is in most cases actually a ‘wallowing’ of the shift rail bore caused by aggressive or incorrect use in conjunction with the vulnerable keyway machined into the bore itself. Under high-stress conditions, the enlargement of the bore could cause deflection on the shift rail, sometimes resulting in serious engagement issues. The new design of the Magnum not only completely separates the links from the bores, but also casts them into the forks for greater precision and a more positive shift feel.

Other points of interest regarding the shift forks are added cross-sectional material for increased rigidity and larger shift pads to promote better wear characteristics.

Retainers

Retainers and fasteners were also re-visited in the design of the Magnum. Unlike the traditional, sometimes ill-fitting, snap rings used in the original T56, Magnum transmissions use split ring designs that offer greater thrust load capacities and help maintain tighter tolerances.

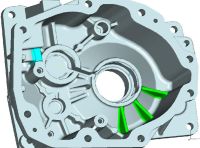

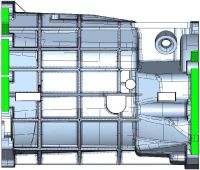

Main Case

While it appears similar to the original T-56 in many respects, the main case and end plate of the Magnum have also undergone extensive modifications in order to safely handle extreme power loads from their intended applications.

Throughout the transmission, provisions have been made, and material has been strategically placed, to prevent leaks under high-stress conditions and increase overall power handling capabilities.

Article:

Please log in to leave a comment.

No Comments Yet