2011-current V6 Mustang T56 Magnum XL 6-speed Swap

Modern Driveline’s T-56 Magnum XL six-speed enables you to step up to better gearing and smoother shifts with fierce reliability.

If you’re driving a 2011-current Mustang with the 3.7L DOHC V-6, we’ll bet you’re frustrated with sloppy shifts, gear clash, disappointing acceleration, and durability issues. And despite overall world-class Mustang build quality, the factory’s Getrag MT-82 six-speed just isn’t up to the job in performance applications. It suffers from an unacceptable failure rate and can’t be described as a user-friendly gearbox. The MT-82 tends to get stuck in gear during hard shifts. It also tends to break. It has a below-par external tunnel-mounted rail style shifter. We’ve even seen bolts fall out of the factory shifter.

|

|

| TREMEC S197 T-56 Magnum XL |

Because the factory Getrag MT-82 six-speed has never been up to the mission it was intended for, Modern Driveline engineers have been working on a TREMEC T-56 Magnum XL six-speed conversion package fully capable and ready for action in your 2011-current Mustang.

For The Most Important Mission — Yours…

TREMEC’s combat-ready T-56 Magnum XL is the latest upgrade in this super gutsy six-speed’s family bloodline. It is already widely known what the T-56 Magnum can do for performance and durability. The T-56 Magnum takes TREMEC’s great OEM technology and applies it to the race-ready TKO five-speed. The result is a bulletproof six-speed transmission that will take up to 700 ft/lbs of torque.

The T-56 Magnum XL goes the Magnum one further with an extended length tail shaft housing that incorporates the shifter and rail into the transmission instead of the sloppy nature of a remote tunnel-mounted shifter. The T-56 Magnum XL has been developed specifically for the S197 Mustang, which makes it a perfect bolt-in swap for the 2011-current V-6 Mustang without special modifications.

What makes the TREMEC T-56 Magnum XL superior is double overdrive for a broad range of driving conditions, a torque capacity of 700 ft/lbs yet with smooth shifts, and the most rugged construction of any six-speed in the industry. Modern Driveline brings you the T-56 Magnum XL along with a complete turnkey installation package you can install in a weekend.

Here’s what you get for your investment:

- TREMEC T-56 Magnum XL Six-Speed Transmission with Shifter

- All Fastening Hardware including ARP

- QuickTime Custom SFI Approved Bellhousing

- Superior Diaphragm Clutch with Multi-Friction Kevlar/Organic

- Modern Driveline U.S. made Lightened Billet Steel Flywheel

- S197 U.S. made Steel Crossmember

- T-56 Magnum XL Mount

- Electronic Reverse Gate Controller

- Wiring Harness & Plugs

- Shift Ball & Collar

- Four Quarts of Synthetic Automatic Transmission Fluid

- High-Speed Dynatech Precision Balanced Aluminum Driveshaft

- Highly Detailed Installation Instructions and Lifetime Tech Support

Request a TAILORED Quote Now »»

How to install

The TREMEC T-56 Magnum XL conversion package for the 2011-current Mustang is an easy weekend install because Modern Driveline has thought of all it for you. This installation has been executed and photographed to show you how easy the installation is and what it will mean for your S197 Mustang driving experience.

This installation is the prototyping of the T-56 Magnum XL conversion kit at Modern Driveline. This means when you buy a T-56 Magnum XL conversion kit from us we have already installed and used it ourselves. We install and use what we sell. And after your purchase, you get personal service from professionals who, like you, are also enthusiasts.

|

|

| TREMEC S197 T-56 Magnum XL |

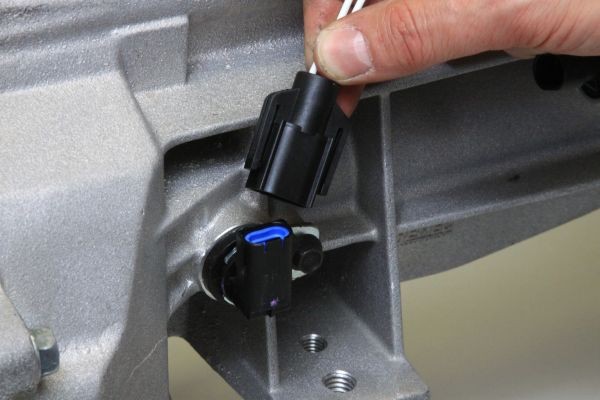

Convenience begins with factory electrical connections that enable you to connect your Mustang with the Modern Driveline T-56 Magnum XL.

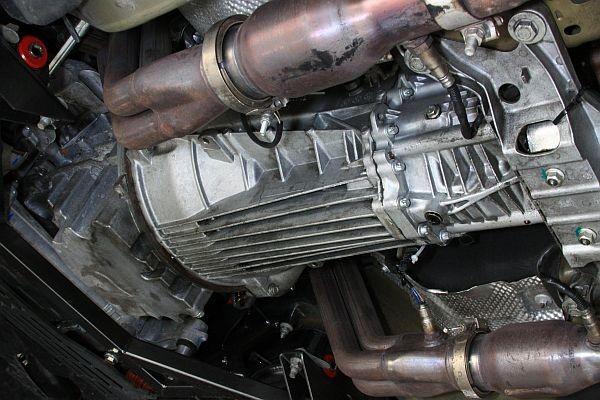

The Getrag MT-82 six-speed was installed in a 2011 Mustang with 3.7L DOHC V-6 power. The V-6 Getrag MT-82 isn’t much different visually from the V-8 version aside from internal differences and gearing. Where the MT-82 falls short is its ability to handle power and its external shifter. Too much is lost between the shifter and transmission. During hard shifting, the MT-82 doesn’t stand up to the vigorous experience of acceleration and speed shifting.

Expect to be pleasantly surprised with the T-56 Magnum XL.

All electrical connections around the transmission including transmission-related connections as well as O2 sensors are disconnected.

The O2 sensors are disconnected because the exhaust system must be removed.

The factory Getrag MT-82 does not have a transmission slip yoke. Instead, it has two flange yokes at both ends of the driveshaft.

This means you will need a T-56 Magnum XL specific driveshaft also available from Modern Driveline.

This is the Getrag’s external rail style shifter, which isn’t as solid or precise as the T-56 Magnum XL’s internal shifter. The Getrag’s Barton Industries short-throw shifter bolts to the body and operates a shift rail at the transmission’s main case. Terrific shifter —however — a problematic transmission.

Center console disassembly for shift removal is easy because the new Mustang is snap together with minimal tool involvement. Pop these panels out and disconnect plugs.

Barton short-throw shifter is disconnected from the transmission tunnel using a 13mm deep well socket on two flange nuts.

Getrag MT-82 is safely supported with a transmission jack and readied for removal. Fluid is drained next.

The transmission crossmember is removed next at four body attachment points and two mount locations. This crossmember not only supports the transmission it acts as a body stiffener.

Once you are confident the battery has been disconnected, disconnect and remove the starter. Starter bolts enter through the bellhousing.

Bellhousing bolts are removed at this time. Some enter through the bellhousing while others attach through the block from the front.

MT-82 Getrag is removed from the chassis. Note transmission is safely secured on a transmission jack.

Internal hydraulic clutch line from the master cylinder above can be disconnected via this line fitting or the factory’s quick disconnect fitting. The quick disconnect will be tied to the new clutch release cylinder.

This is one of the Getrag MT-82’s weaknesses. The Barton short-throw shifter is a good shifter in its own right. However, how it is tied to the transmission is the weakness. With the MT-82 you get gear clash and broken parts. We’re about to change all of that with the T-56 Magnum XL from Modern Driveline.

Clutch and flywheel are removed at this time to make way for a new Superior clutch and flywheel from Modern Driveline. We’re going to take the time to do a little side-by-side comparison to see how clutches and flywheels stack up.

The existing flywheel surface is checked with a straight edge, which indicates excessive heat and wear. Bluing indicates extreme heat damage from competition.

Examination and removal of the old flywheel is a forensics study in why there was clutch friction failure due to slippage.

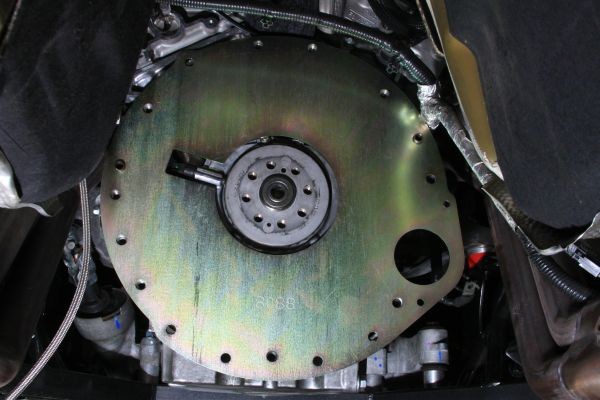

This is the 3.7L DOHC engine’s crank sensor and reluctor (trigger) wheel. There is no need to remove the reluctor wheel except to inspect the engine’s rear main seal for leakage. This is a part you certainly don’t want to forget when it is time for assembly.

If there is any indication of rear main seal leakage, this is the time to correct it.

Reluctor wheel is checked for proper fitment to the new Modern Driveline flywheel.

The clutch release slave cylinder is bench-bled as shown to remove all air bubbles prior to installation.

The clutch release slave cylinder is installed next as shown.

The QuickTime engine/bellhousing separator plate is positioned and good to go. It is a perfect fit and cleared for mass production. The crankshaft reluctor wheel has been installed and checked for proper installation. All holes must line up.

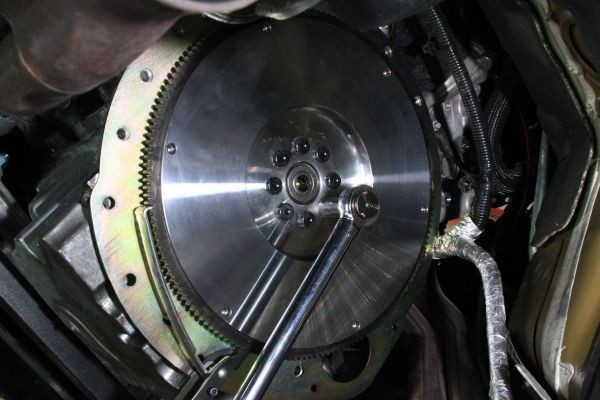

Modern Driveline steel flywheel is indexed and installed, torquing all bolts in a crisscross fashion to 65 ft/bs in one-third values. A thread locker has been used on bolt threads.

Superior clutch and pressure plate are positioned, properly indexed, and installed with bolts torqued to 25 ft/lbs in crisscross fashion in one-third values. The clutch alignment tool included in the kit is used to achieve perfect disc alignment. Modern Driveline suggests the use of a discarded input shaft if you can find one for alignment purposes.

QuickTime blow proof bellhousing is checked for proper indexing and permanently installed.

Factory Nippondenso reduction gear starter is reinstalled and connected.

Side By Side Comparison

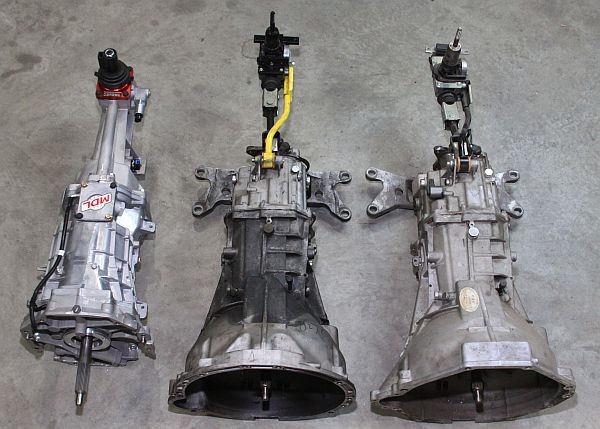

Side by side from left to right are three Mustang six-speed transmissions — the TREMEC T-56 Magnum XL, Getrag MT-82 for 3.7L V-6, and the Getrag MT-82 for the 5.0L Coyote V-8. This demonstrates the durable demeanor of our TREMEC T-56 Magnum XL not to mention its right sized personality for the S197 Mustang. The T-56 Magnum XL’s rugged construction along with an integral shifter offers you confidence because it is designed right into the transmission instead of being an afterthought attached to the vehicle. Grab gears and get after pavement with confidence instead of the anxiety of a missed shift. What’s more, because the T-56 Magnum XL is geared to be more user friendly, acceleration is crisp to where you don’t run out of engine before it is time to upshift into second.

The TREMEC T-56 Magnum XL offers you so much more in a transmission than the factory Getrag MT-82 due to its world class engineering. TREMEC has taken the original bulletproof T-56 and blended in the nuances of the TR-6060 to create the T-56 Magnum. And because it bolts right into your S197 Mustang, it gets to wear the name Magnum XL. The Magnum XL is the best driving, smoothest shifting, toughest six-speed in the industry. And it is geared just right for your 3.7L DOHC V-6 Mustang for great acceleration and cruising including two overdrive ranges for the open highway.

Real Beefcake

With gear ratios being the only direct carry over from the original T-56, the Magnum XL is truly a brand new transmission from the ground up designed specifically for your S197 Mustang. Of the many substantial upgrades, those listed below will, in the long term, likely be those most pertinent and sought after features that will set the T-56 Magnum apart from the rest.

- 26-Spline Input Shaft

- 31-Spline Output Shaft

- 85mm Center To Center

- Internal Rail Shifter for precision shifts and durability

- 700 ft/lb Torque Capacity

- Can withstand an 8,000 rpm shift

- Triple cone synchronizers on gears 1-4, double cone synchronizers on gears 5-6, as well as reverse. These are race proven synchronizers

- Bolt-In S197 Swap with no Modifications

Compare Real Difference

| First | Second | Third | Fourth | Fifth | Sixth | |

| MT-82 V-6 | 4.236 | 2.538 | 1.665 | 1.238 | 1.00 | .70 |

| MT-82 V-8 | 3.660 | 2.430 | 1.690 | 1.320 | 1.00 | .65 |

| T-56 Magnum XL | 2.660 | 1.780 | 1.300 | 1.000 | .74 | .50 |

| T-56 Magnum XL | 2.970 | 2.100 | 1.460 | 1.000 | .80 | .63 |

Modern Driveline’s Bruce Couture and Paul Coffey position the T-56 Magnum XL splining its input shaft into the Superior clutch disc. Because the QuickTime bell and Superior clutch have both been properly indexed, installation is easy.

The Modern Driveline T-56 crossmember is lined up and installed at this time. Everything lines up as expected.

Bruce measures from tailshaft housing to the Mustang’s 8.8-inch rear axle flange to ascertain proper driveshaft measurement. He wants to see ½ to ¾-inch of slip yoke exposed with vehicle on the ground.

The Getrag MT-82’s aftermarket aluminum shaft has been replaced with this aluminum Dynotech piece from Modern Driveline. Slip yoke has been lubed up with transmission assembly lube to prevent seal damage.

Driveshaft flange is checked for compatibility and looks like a good fit. Slip yoke is checked for proper transmission penetration before a thread locker is used on these bolts. They are torqued to 70-95 ft/lbs.

Prototyping includes fabricating an experimental wiring loom for the conversion, which will be produced as a mass production piece you can plug and play with.

Request a TAILORED Quote Now »»

This is the T-56’s electronic speedometer ratio adaptor, which does two things. It changes the pulse count of the transmission to match the MT-82 as well as the wire configuration from three wire to two wire. Dip switch allows for differences in tire size and axle ratio, and no need for the dealer to recalibrate.

Exhaust system and O2 sensors are reinstalled at this time. Use anti-seize on O2 sensor threads.

Dexron III (It is Dexron) automatic transmission fluid is serviced into our T-56 Magnum XL. Because manual transmission tolerances are tight these days and we are seeking a smooth shift, never use high viscosity gear lube in these transmissions.

If you’re looking to upgrade your Mustang send us your details and we’ll get back to you with a quote. Or call…

208-453-9800

Please log in to leave a comment.

No Comments Yet